Custom Buckles Are Totally Professional

Table of ContentsCustom Buckles Are FantasticCustom Buckles Are Efficient & InformativeCustom Buckles Are Effective & AffordableCustom Buckles Are Very AccommodatingCustom Buckles Are The Most FriendlyCustom Buckles Are The Most FriendlyVery Impressed With Custom BucklesCustom Buckles Are Professional & Polite

Individuals have traditionally manufactured products using raw materials (custom buckles). As well as in specific cases, they still do. Hand producing includes making use of basic tools via even more typical procedures. This type of manufacturing is typically connected with decorative art, fabric manufacturing, leatherwork, woodworking, and also some metalwork. Handmade goods are labor-intensive and also require a great deal of time.One-of-a-kind hand-crafted style products can be marketed at a higher cost contrasted to something mass-produced.

Ford promoted mass-production methods in the very early 20th century. Computer systems and precision digital equipment have considering that permitted business to pioneer modern manufacturing techniques.

Custom Buckles Are Totally Professional

The skills called for to operate equipments and also create manufacturing processes have substantially changed gradually. Many low-skill manufacturing jobs have actually moved from created to creating nations due to the fact that labor in creating nations often tends to be cheaper. Premium items that require accuracy and experienced manufacturing are commonly created in established economies.

The quantity and number of goods made have actually enhanced, the number of workers needed has declined. Producing worth included (MVA) is an indication that compares an economic climate's production result to its total size.

This procedure, which converts raw materials into completed items, is called production. Organizations can still make use of human labor to transform these products by hand.

Custom Buckles Are Totally Professional

The advent of 3D printing is making it simpler for individuals to produce finished items themselves, without ever before leaving their very own residences.

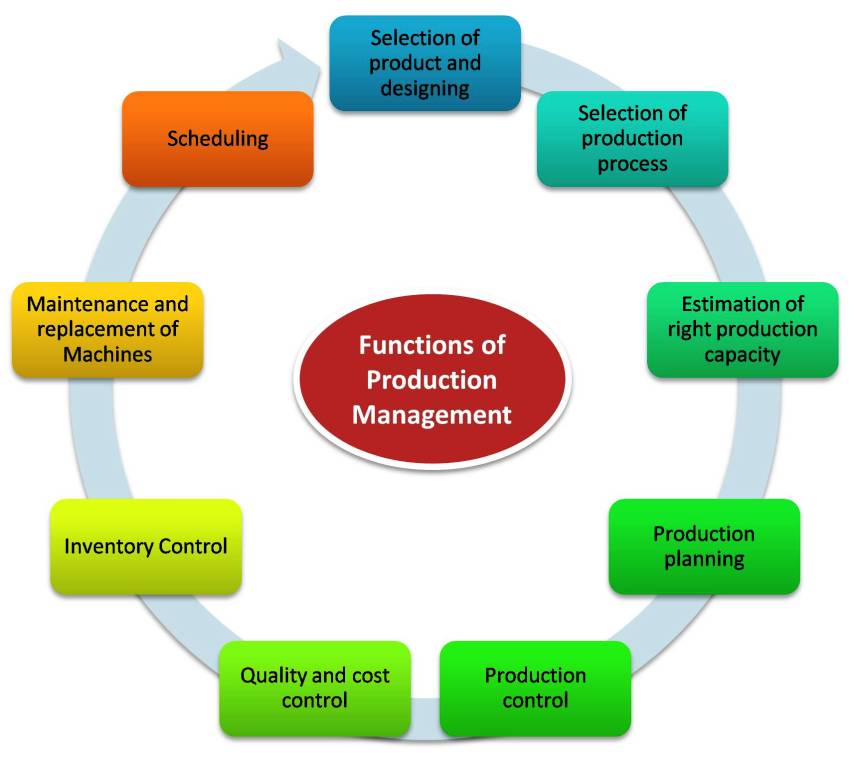

During manufacturing preparation, supervisors establish exactly how goods will certainly be produced, where manufacturing will take place, as well as how making facilities will certainly be laid out. What are the features of producing monitoring? The above functions of manufacturing management are quickly talked about below. Option of Item and also Style. Option of Production Process. Picking Right Production Ability.

Production generates much more financial task than other industries. No other market comes close to these numbers. What are operations features? Procedure feature is the term used to explain just how the core operation of the company is developed as well as features. In making it is just how the raw materials are transformed into an useable item.

Custom Buckles Are Very Quick

What is an instance of manufacturing? The meaning of manufacture is the procedure of making items from resources. An instance of manufacture is the making of autos in manufacturing facilities. To manufacture is specified as to make something from raw materials by hand or making use of machines. An example of to manufacture is to make clothes from cotton.

For example, manufacturing processes such as die spreading, which appropriate for big volumes, are totally inappropriate for little volumes; methods such as those entailing metal removal (machining from a solid) might have to be used for smaller sized manufacturing quantities. While a lot of the factors stated formerly have contradictory demands (e.

It is currently extensively identified that the design as well as production functions need to be very closely connected if these goals are to be satisfied. This close, as well as currently inseparable, association is described by many names in the published literature: design for manufacturability (manufacture), style for excellence, simultaneous engineering, or simultaneous engineering.

Custom Buckles Do A Great Job

Requirements of dimensions and resistances (selection of machinery).

Processing operations transfomi the product from one state of completion into an advanced state of conclusion. No products or elements are assembled or contributed to complete the change. Rather, power (i. e., mechanical, warmth, electric, chemical, etc) is contributed to transform the shape of the frying pan, get rid of material from it, alter its physical residential properties, or achieve various other forms of work to change it.

Custom Buckles Are Totally Professional

Metal casting as well as plastic molding are examples. Secondary processes follow the standard procedure and also are carried out to offer the workpart its tinal preferred geometry.

Procedures to boost physical buildings do not perceptibly change the physical geometry of the workpart. Instead, the physical residential properties of the product are enhanced somehow. Heat-treating operations to reinforce metal components and preshrinking used in the garment industry are examples in this classification. Ending up operations are the linal procedures carried out on the workpart.

Very Happy With Custom Buckles

Because the workpart has to be directed via a number of procedures, only the last operation generates the tinished part. The other operations create work-in-progress for prospering procedures. As a by-product of all producing procedures, some scrapmaterial as well as waste outcomes. The scrap is in the type of metal chips (machining procedures), skeletal system (sheet steel pressworking procedures), spruc as well as runner (plastic molding), and so forth.

Setting up as well as joining procedures constitute the 2nd major kind of manufacturing operation. ln setting up, the identifying function is that two or more separate parts are collaborated. Included in this category are mechanical fastening operations, that make use screws, nuts, rivets, and so forth, and also view publisher site signing up with procedures, such as welding, brazing, as well as soldering.

A means of moving and keeping materials in between the processing as well as setting up operations need to be provided (custom buckles). In a lot of manufacturing plants, materials invest even more time being relocated and also stored than being processed. ln some situations, the majority of the labor cost in the manufacturing facility is consumed in handling, moving, and saving products.

Very Happy With Custom Buckles

In Chapters 14 and also 15 we take into website link consideration the materials taking care of as well as storage space feature and also the methods whereby it can be automated. lnspection and also screening are usually taken into consideration part of top quality control. The function of inspection is to identify whether the manufactured product meets the established style requirements as well as requirements.